We are judged by what we Finish not by what we start

Its Prestigious clients list is

what describes the company. Yes, it is M/s. Sandstorm Equipment Company the name Total Surface Engineering Solution started in the year 1995 in Bangalore,Southern part of India. Bangalore is home to Quality Machine Tools and the Machine-building industry in India, it is

also home to Information Technology, Bio-Technology, and Aero Space Technology. The world can find thousands of Modern Specialized Ancillary Support Systems in Bangalore which help industries produce the best quality, design, and finish to compete

in the international market.

M/s. Sandstorm Equipment Company is specialized in the manufacture of field-proven types of finest equipment for the Surface Finishing Industry forthe past 15 years. Sandstorm's success is attributed to its

quality products philosophy.

M/s. Sandstorm’s few finest equipment are -

- Abrasive Eco Blast

Cabinets - Standard Cabinet type Blaster are used for blasting small components

which can be loaded into the chamber and blasted manually by the operator

standing outside the cabinet with the use of hand holes and view glass.

- Portable

Abrasive Blasting Machines (P7 Range) - Sandstorm

Portable Abrasive Blasting Machines are field-proven, robust, user friendly,

and economical. Sandstorm P7 machines are of the best quality the machines are

hydraulically tested to 250 PSI.The Sandstorm P7 machine comes with an option of

with or without remote control and dead manhandle.

- Abrasive Blast Room Systems - Blast rooms are large

blasting enclosures designed to handle work too large even for the biggest size

job. A blast room contains both the workpiece and the operator. A dust

collection system provides visibility; recovery floor sections convey the spent

abrasive to an abrasive cleaning system which returns only good abrasive to the

blast machine.

- Special

Purpose Blasting Machine

- Tumble Blast Systems - Tumble Blast systems are usually used in the blasting of small

components which are loaded into the tumbler in batch quantities while the

components are tumbling the blasting goes on simultaneously through nozzles

which results in the complete coverage of the components. The Tumbler can be a

belt tumbler, tumble basket, or drum-type tumbler. Only the loading is done

manually and the rest of the operation is automatic, these are special purpose

machines (SPM) designed as per customer requirements.

- Shot Peening Systems -

Shot peening is a cold working process used to produce a compressive residual stress layer and modify the mechanical properties of metals. It entails impacting

a surface with shot (round metallic, glass, or ceramic particles) with force sufficient to create a plastic deformation. It is similar to sandblasting, except that it operates by the mechanism of plasticity rather than abrasion each particle functions

as a ball-peen hammer. In practice, this means that less material is removed by the process, and less dust is created.

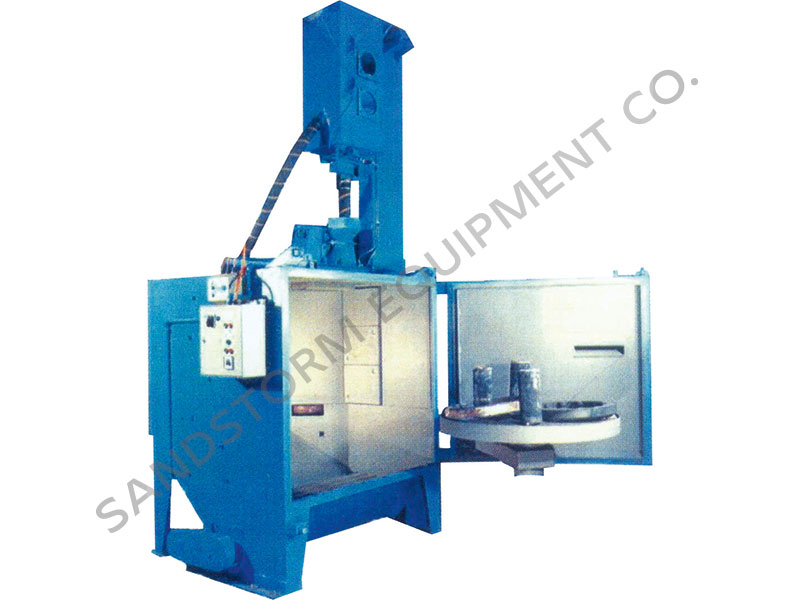

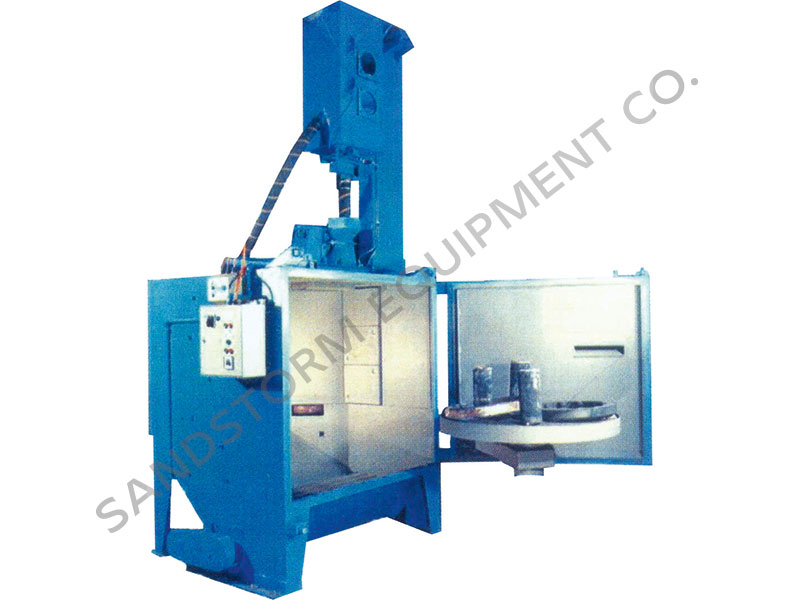

- Airless Swing Table Shot Blasting Machine

- Paint Spray Booth Systems -

Sandstorm manufactures low-cost

economical paint booth systems for industrial needs. Sandstorm paint booths are

the dry and wet type with down and side draft systems. The paint fume

extraction fans are of high quality and are made in-house and the filter fabric

used is of a very high quality ensuring high performance, low maintenance cost

and is field-proven.

- Blasting Spares And <font color="#000000" face="Calibri, sans-serif">Consumable</font>